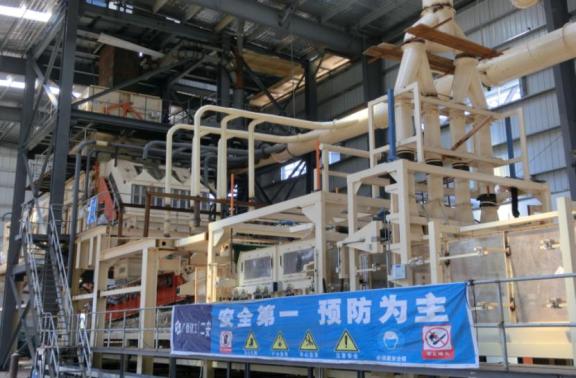

China forma machinery group co., LTD., independent research and development with independent intellectual property rights of continuous flat wide wide man-made board production line, extending the China forma advantage on man-made board machinery and equipment, fully embodies the advanced equipment of production line in each section.Its research and development of continuous press was listed in China national high technology research and development program (863 program) "MuZhu advanced processing and manufacturing technology research" project "man-made board continuous roller and precision control technology" research, China is based on both the lead horse is outspread, China forma group has become a real sense of continuous pressing can provide a full range of man-made board production line equipment of the company.Suzhou sufoma machinery company took a group of continuous press assembly and the r&d, design, production, main single machine manufacturing work.

A good, the product quality stability;

B, thickness precision, continuous press of longitudinal and transverse pressure can be automatically adjusted, the thickness tolerance can be controlled within + / - 0.1 mm;

C, elasticity sheet specifications, width 4 ~ 9 feet, the thickness of 3 ~ 40 mm;

D, raw material consumption, low compression of slab heating, almost at the same time, the solidified layer thin, small amount of sanding and transverse cutting edge amount less;

E, power consumption, low heat consumption, the production process, the steel strip is always in contact with the slab, pressurized system stable fluctuation is small, no time;

F, quick production adjustment in a short period of time, which can realize the online adjustment of the slab size, density and thickness.

Board type MDF/PB

Width 4-9 ft

Thickness after sanding 4 – 25 mm

Sanding margin 0.6 – 1.4 mm

Running speed max. 1.300 m/s

Production standard

Standard 1,220~2,440 x 2,440 mm

Thickness before sanding max. 2,745 mm

Design parameter

Forming machine / Press

Operation height 1,500 mm

Plate forming height max.2,650 mm

Width after cutting max.2,545 mm

Press

Operation height 1,500 mm

Speed 60 – 1,200 mm/s

Cooling and stacking

Operation height 1,500 mm

Plate stack height max.1,000 mm

Waste plate stack height max.750 mm

D-D cutting length after press max.5,600 mm

D-D saw length About 500 mm

A、Forming machine of Density fiberboard

Function: is the role of the shop is installed loose dry fiber through measuring uniform shop, after quashed, form conforms to the requirements of the continuous slab, for the next working procedure. This equipment is the main technical characteristics:

A. shop installed in consideration of measuring pocket of feed and discharge way, for the first time in the form of double helix conveyer.

B. roll from the pavement structure and material method and adaptability to raw materials, through both flat device structure to improve fiber shop is horizontal and vertical density uniformity.

C. Based on machine shop and all flat device effectively reduce the magnitude of the fly back shop is on the slab surface even get free quashed.

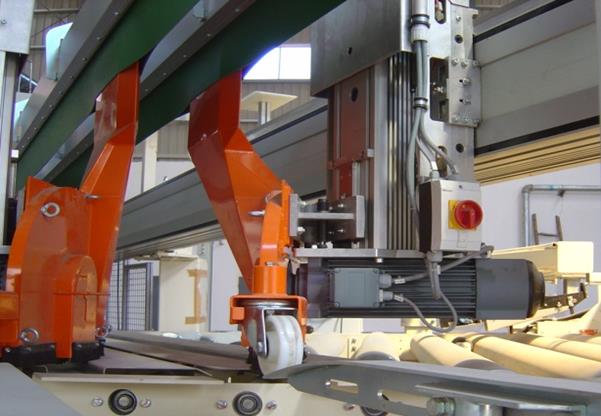

B、 High speed saw

Function: to continuous press out the slab cutting to meet the requirements of the process of slab, convenient at the back of the cooling and stacking.

A. single-girder flying saw structure is used in high-speed saw blade motor redirection is decorated, lower fuselage of space size, compact structure and improve the body rigidity.

B. saw groups are new form of transmission, mechanical and sealing performance is better.

C. saw components are lightweight design to ensure that the rigid at the same time, the weight is only 1/2 of similar products, high speed cutting is more stable;

D. move a supporting would lubricating oil supply system, control the average amount of lubrication, improve operation precision and service life.

E. adopts advanced control technology, precise feeding speed control for the material, to ensure cutting kerf shape.

C、 Air flow forming machine

Function:

Is the role of the shop is installed in different shape and size of the core layer table sizing shavings continuous, evenly paving, respectively, and achieve common shaving board surface gradient, the structure of the core layer of mixed use requirement.

A. survey precision than the traditional mechanical survey precision is higher.

B. the surface flow field structure makes the pavement surface more close.

C. core layer shop USES the optimization structure, make the slab internal bond strength improved significantly.

D. adjustable horizontal airflow, air distribution is more even, it is more convenient to adjust.

E. new design of feed system enables more uniform feeding, packing density is more stable.

F. lateral fabric more even

G. pavement width adjustable, can meet the needs of users of different width wide

D、Pathway dryer

Function:

Will be allowed to dry wet shaving conform to the requirements of the process of dry wood shavings

A, dry flue gas flow more in line with the particle board surface than the core layer material the making craft of high moisture content, the more excellent product quality,

B, drier waste heat recycling, scrap and increase with the decreasing of material moisture content, the characteristics of energy saving, high thermal efficiency is obvious; Configuration of the reciprocating grate waste combustion furnace, more in line with the characteristics of particle board producers in China, sanding powder and plate waste as the main fuel, not only solved the problem of waste pollution, and save fuel spending, is "kill two birds with one stone" environmental protection and economic benefits;

C, drying medium by traditional non-contact type rotor type dryer heat conduction oil or saturated steam into adjustable hot flue gas to heat exchange, direct contact with the shavings effectively avoids the heat loss caused by the thermal medium, to improve the drying efficiency, shaving form good;

D, three layer dryer cylinder body integration design, from a similar rotor drier main shaft fracture risk, safety and reliability to further strengthen;

E, compared with the same output rotor drier, the energy saving, low cost, high thermal efficiency, good reliability, etc;

F, electronic control system by manual or automatic PID control and human-machine interface, achieving full automatic

.

SINOMACH

SINOMACH

Website map| Copyright notice| Online Service| Contact us

Copyright © 2012-2018 SUZHOU SUFOMA MACHINERY CO.,LTD All Rights Reserved.

Su ICP No. 19075173

WeChat of Sufoma

WeChat of Sufoma